Repairing and Soldering BGA

Electronic Devices and Gadgets are getting smaller and slimmer day by day. All this is possible because of technological progress and development in electronics. Top Electronic Companies in the World are in competition to make the smallest and slimmest gadgets. SMDs or Surface Mount Devices and BGA or Ball Grid array are two electronic components responsible for making electronic devises and gadgets smaller and slimmer.

Let us understand BGA. What is BGA (Ball Grid Array) and Why BGA?

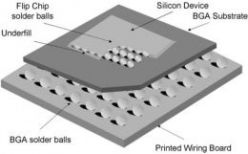

BGA or Ball Grid Array is one type of packaging for Surface Mount Technology (where SMD electronic components are actually ‘mounted’ or affixed on the surface of the SMT printed circuit board). A BGA package has no leads or pins. The Ball Grid Array gets its name because it is basically an array of metal alloy balls arranged in a grid. These BGA Balls are normally Tin/Lead (Sn/Pb 63/37) or Tin/Lead/Silver (Sn/Pb/Ag).

BGA offer many advantages over SMDs or Surface Mount Devices:

The PCB or Printed Circuit Board in today’s electronic devices and gadgets densely populated with electronic components. The size of the Circuit Board will increase with increase in number of electronic components. In order to squeeze the size of the PCB, SMDs and BGA Packages are used because both SMDs and BGAs are smaller and slimmer in size and occupy very little space on the PCB. BGA components provide better solution for many circuit boards, but care is required when soldering BGA components to ensure that the BGA solder process is correct and is reliable.

BGA also offers following advantages:

Improved PCB design as a result of lower track density.

The BGA package is robust.

Lower thermal resistance.

Improved high speed performance and connectivity.

BGA Soldering

During the initial stages, BGA technology was a matter of concern. People had

BGA Package

doubts on solderability and reliability of BGA components. In BGA, the pads are under the device and not visible and hence it is necessary to ensure the correct process of soldering and inspection.

Today, BGA solder techniques is tried and tested and has been proved and trusted to be very reliable. It has also been learnt that once the process is WHERE set up correctly, BGA solder reliability is mush higher than that for quad flat packs (QFP) or any other SMD Package.

Reflow Soldering techniques is used to solder BGA. Reflow soldering technique is used to solder BGA because it helps the whole assembly to be brought up to a fixed temperature in order to melt the solder or solder balls underneath the BGA components.

For any BGA soldering, the solder balls on the package have controlled amount of solder. Solder ball in various sizes of 18 mil, 24, mil 30 mil etc are available. When the Board with the solder balls and BGA Package is placed in the reflow oven, it gets heated and the solder melts. Surface tension causes the molten solder to hold the package in the correct alignment with the circuit board. It in important to take care of the composition of the solder alloy and the soldering temperature so that the solder does not completely melt, but stays semi-solid , so that the solder balls stay separate from each other and do not result in any bridging.

Inspection of BGA solder joint

BGA inspection is one of the toughest jobs. It becomes extremely difficult to inspect the BGA joints since the solder is underneath the BGA Package and are not visible. The only satisfactory means of testing BGA Solder Joints is X-rays. X-Ray helps to see the joints underneath the package and thus helps in inspection.

BGA Rework / Repairing / Hand Soldering

Rework and hand soldering of BGA Packages is the toughest part. It needs practice to do the job. Let us understand Desoldering and soldering of BGA packages:

Desoldering BGA

The most common practice to desolder BGA is hot air. Here are the steps to desolder BGA Package using Hot Air:

1. Apply liquid solder flux on the sides of the package.

2. Preheat the package from both top and bottom. Heat can be given from the bottom using a preheated while heat from the top can be given using a Hot Air Rework System. Hakko FR-820 is the best available preheater while Hakko FR-803 is the best economical Hot Air SMD / BGA Rework System

3. Now using the correct BGA Nozzle, give heat on top of the BGA Package.

4. The solder balls underneath the BGA package will melt. Pick up the package with a Tweezer of using vacuum pick-up.

Soldering BGA

Again the most common practice to solder BGA is hot air. Here are the steps to solder BGA Package using Hot Air:

Once the BGA Package is removed, clean the pad and remove any excess solder from the board.

1. Apply Flux Paste (Not Liquid Flux) on to the pad. Paste flux will help solder balls to stick so that they do not fall or change position.

2. Place solder balls very carefully on the pad.

3. Apply paste flux to the bottom (soldering side) of the BGA package.

4. Carefully place the BGA Package of the solder balls.

5. Preheat and then apply Hot Air from both top and bottom.

6. Solder balls will melt and get soldered.

BGA technology and the BGA soldering is very reliable if done using the correct procedure. A BGA has less resistance to heat and hence there is lesser or no damage due to overheating.

Capacités

Capacité PCB rigide

Capacité PCB flexible

Capacité d'assemblage PCB

Équipement PCB

Équipement d'assemblage PCB

Méthodes de paiement

Prix spéciaux

Transporteurs

Support pour amateurs

Certificat

Assistance clientèle

Suivez-nous

Tel: 1-905-339-2881

Email: sales@goldphoenixpcb.com , tech@goldphoenixpcb.com

Copyright Gold Phoenix PCB Co., Ltd. 2011 - 2025

Tel: 1-905-339-2881 Email: sales@goldphoenixpcb.com , tech@goldphoenixpcb.com

Système de contrôle qualité | Service produit

| Liens

Copyright Gold Phoenix PCB Co., Ltd. 2011 - 2025