Metal Core PCB an Ideal Solution to Thermal Issues in PCB and PCBA

The rising specs of electronic products leads to extensive applications of large scale integrated circuits (ICs) and Surface Mount Technology (SMT) assembly in modern electronics manufacturing services. Moreover, circuits have been moving towards miniaturization, light weight, multiple functions, high performance, high speed and high reliability. Constant expansion of component density causes gradual increasing of heat flow density. As far as semiconductor devices are concerned, too high temperatures will possibly lead to variation on electrical performance. Whenever Tj (junction temperature) rises by one time, thermal breakdown will be caused if serious. If thermal issues fail to be suitably solved, component specs will definitely suffer from instability, further reducing products' stability and reliability with their missions hung in the air. In conclusion, thermal issues of Printed Circuit Boards (PCBs) are so protruding that much attention has to be especially paid to them for sake of high performance of electronic products.

Up to now, thermal dissipation methods leveraged by high-tech circuits can hardly meet the demands on thermal dissipation WHERE set by later circuits, calling for a new type of thermal solution. Based on discussion on some prevalent thermal dissipation methods used in electronic products, Metal Core PCB (MCPCB) is introduced as a solution to thermal issues in advanced circuits.

Traditional Thermal Dissipation Method

Heat generated by circuit mainly derives from component heat, PCB board heat and heat as a result of exterior conduction among which component heat accounts for the majority. Therefore, components' thermal dissipation issue receives the most concern during component layout and PCB design. Thermal resistance plays a significant role in thermal design and the aim of thermal design is to reduce thermal resistance conducted on the path of thermal conduction with heat quickly conducted to heat sink such as radiator. Overall thermal resistance between electronic component and heat sink can be classified into device-level, assembly-level and system-level. Device-level thermal resistance is also called internal resistance while assembly-level resistance called exterior resistance and system-level resistance called final resistance. Relationship between internal and exterior resistance and Tj of components is equivalent to that between component Tj and thermal resistance, conforming to the following formula:

Tj=Pd x (Rjc+Rcs+Rsa)+T0

In this formula, Tj refers to component junction temperature; Pd refers to device power; Rjc, Rcs and Rsa respectively refer to thermal resistance from junction to enclosure, enclosure to heat sink and heat sink to complete appliance. T0 refers to initial temperature and Rjc is a fixed characteristic value. Thus, thermal resistance reduction can only be achieved from the perspectives of Rcs and Rsa.

Device assembly modes play a significant role in thermal dissipation and different types of assembly modes require different thermal dissipation methods.

• Convex Platform Structure

When component shell directly contacts with circuit board and is assembled on the front side, coverplate convex platform should be leveraged for thermal dissipation. Convex-platform thermal dissipation refers to the process that a convex platform for thermal dissipation is added to corresponding coverplate in accordance with heat sink positions in circuit with thermal-conductive insulating mat used to be contacted with convex platform.

This thermal dissipation mode acquires cooperative work of structure and PCB board design. Convex platform count, positions, height, area and thermal-conductive mat thickness are all closely related with circuit board performance. Plus, assembly deviation has to be taken into consideration as well. So this mode brings many difficulties to PCB design, PCB manufacturing and PCB assembly (PCBA).

• Thermal Conductive Tape

If component pins are directly soldered onto PCB board without component shell directly contacted with circuit board, thermal conductive tape can be leveraged for thermal dissipation. Thermal conductive tape is usually made of copper, featuring two assembly types. One is to get thermal conductive tape assembled on component top with the other end connected with heat sink. The other is to assemble components onto circuit board through thermal conductive tape with the other end connected with heat sink. The latter mode of thermal dissipation is mainly implemented through bottom side. Adhesive thermal-conductive insulating mat can be used between component and thermal conductive tape.

This mode calls for structural assembly between components and thermal conductive tape that should both maintain a good contact with thermal-conductive mat and components and should not impose too large stress to component pins. To fix thermal conductive tape, fixed locating holes should be made on circuit board so that PCB tracing and layout will be badly affected. Therefore, this mode doesn't work for high density PCBs.

Furthermore, component pins will be affected when thermal conductive tape is vibrating, which has to be carefully considered.

• Thermotube

Thermotube takes advantage of evaporative refrigeration with thermotube two-end temperature difference extremely large so that heat can be fast conducted. Generally speaking, thermotube is composed by tube shell, wick and end cover. Internal thermotube features a negative pressure state with some liquid with low boiling point filled in. Moreover, this type of liquid is easy to be volatilized. Liquid absorption core is available on tube wall, made from capillary material. One end of thermotube is for evaporation while the other for condensation. When evaporation part of thermotube is heated, liquid in capillary will be evaporated instantly and steam flows to the other part under micro stress with heat generated and recondensed to liquid that will flow back to evaporation part of thermotube under capillary stress.

Although thermotube features dramatically thermal dissipation capability, it hasn't developed maturely enough to be accepted by small components. Therefore, there's still a long way for thermotube to go in thermal dissipation of PCB boards.

MCPCB for Better Thermal Dissipation

• Introduction of MCPCB

Along with constant development and optimization of materials science and processing technologies, MCPCBs have been extensively applied in the US and Japan. Under equivalent external application environment, MCPCBs perform more excellently than any other type of PCB boards in thermal dissipation, representing a high level of worldwide high-power electronics assembly.

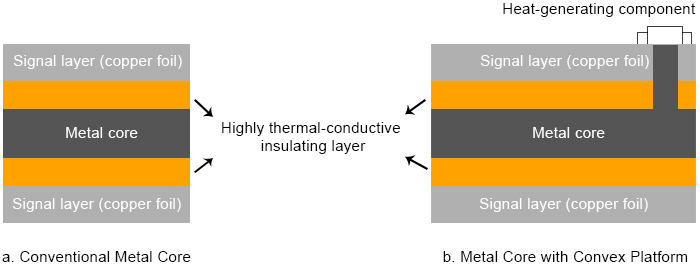

MCPCBs take advantage of thermal-conductive metal, copper for example, in some layer of a multilayer PCB. MCPCBs dissipate heat externally through metal core or carry out fast thermal dissipation by getting connected with external heat sink. When it comes to high density circuits, PCB boards compatible with SMT assembly or circuits with so many through hole components assembled on, highly thermal-conductive MCPCBs have to be picked up. A metal core with good thermal dissipation is first embedded into a multi-layer PCB whose layers can be connected through plated through holes that can conduct heat at metal core and its surface. MCPCB structure can be displayed in the following figure.

• Merits of MCPCB

Compared with traditional thermal dissipation modes, MCPCBs feature unbeatable merits on thermal dissipation. MCPCBs can improve products' power density and reduce the needs to assemble radiators and other hardware. Moreover, product volume can be shrinked with hardware and assembly cost going down. Finally, MCPCBs play an active role in increasing products' reliability and shielding electromagnetic wave with eletromagnetic interference downsized.

Due to large copper density, MCPCBs share obviously better quality than any other type of PCBs. However, application of MCPCBs will not bring forward higher weight due to fewer applications of radiators and accessories that are usually equiped on other types of PCBs. Two tips concerning MCPCBs can be stuck to when deciding on MCPCBs:

Tip#1: Agreeable copper core thickness should be selected;

Tip#2: Aluminum core PCB can be selected as well.

Capacités

Capacité PCB rigide

Capacité PCB flexible

Capacité d'assemblage PCB

Équipement PCB

Équipement d'assemblage PCB

Méthodes de paiement

Prix spéciaux

Transporteurs

Support pour amateurs

Certificat

Assistance clientèle

Suivez-nous

Tel: 1-905-339-2881

Email: sales@goldphoenixpcb.com , tech@goldphoenixpcb.com

Copyright Gold Phoenix PCB Co., Ltd. 2011 - 2025

Tel: 1-905-339-2881 Email: sales@goldphoenixpcb.com , tech@goldphoenixpcb.com

Système de contrôle qualité | Service produit

| Liens

Copyright Gold Phoenix PCB Co., Ltd. 2011 - 2025